Founded in 2004, Delta is driven by an unwavering commitment to quality and technology, a responsible attitude towards customers, continuous research and development, and the dedication of its employees. Delta has flourished and has become a high precision company in the high-speed rail, precision instrument equipment and medical device industries. A reliable partner for microparts manufacturing, Delta provides customers with one-stop manufacturing solutions from part processing to finished product assembly, from the research and development stage to the mass distribution stage. The main processes are:

CNC workshop: CNC core machine, CNC turning and milling machine

Finishing workshop: micro hole processing, wire rolling, high precision grinding, laser welding, laser cutting, wire cutting, welding, etc

Surface treatment: Teflon spray, electrolytic polishing, passivation, etc

Injection molding workshop: precision injection molding, insert injection molding, micro-injection molding, 100,000 clean (ISO Grade 8)injection molding, 10,000 clean (ISO Grade 7) cleaning packaging assembly, etc

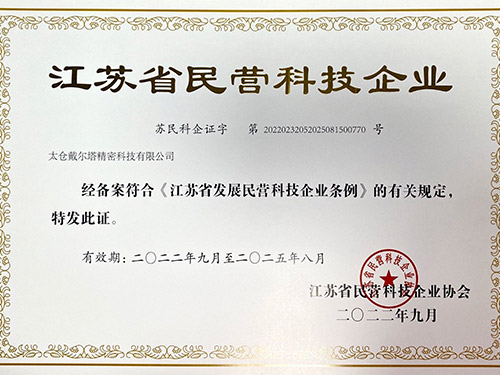

Delta precision machining technology has won a number of patents, won the high-tech enterprise certificate issued by Jiangsu Provincial Science and Technology Department, and Jiangsu Provincial private technology enterprise certificate. Delta has passed IATF16949 and ISO13485 quality system certification and ISO14001 environmental management system, with more than 20 years of experience in precision machining, is a modern private factory with standardized management.

We have always attached great importance to the customer's quality specifications, no matter how strict, we will do our best to meet.

Over the past decade, Delta has developed a wide range of high-precision components for large customers. With the technical advantages of our company, we know how to solve all the problems you may encounter.